LED Explosion Proof Lighting

No products were found matching your selection.

No products were found matching your selection.

An explosion-proof LED light is a lighting fixture designed to prevent the occurrence of explosions in hazardous environments. Safety and precaution have become major concerns for businesses worldwide, leading to continuous efforts by various organizations to establish stricter safety protocols in the workplace. Company managers are now more aware of minimizing both human and financial losses.

The importance of safety equipment, such as explosion-proof lighting, has been highlighted because they help workers operate effectively in hazardous environments such as oil refineries, chemical plants, food industries, and mines. Generally, a hazardous area is a location with a high concentration of flammable particles, liquids, gases, fibers, dust, and other substances that can cause a fire. All equipment used in a hazardous area must be designed to be non-sparking, and explosion-proof lighting fixtures are one of them.

Explosion-proof lighting does not refer to lighting fixtures that are resistant to explosions but rather to their ability to prevent external explosions in hazardous locations. Explosion-proof lights, often referred to as Ex Lighting, ensure that any sparks within the fixture are eliminated, preventing potential fires or explosions.

These lights are made of a thick metal or steel housing with a sturdy lens, blocking the internal sparks from escaping and mixing with combustible sources in the surrounding atmosphere. This reduces the risk of accidents and improves the overall safety of workers, individuals, and valuable assets at the site.

Installing explosion-proof lighting fixtures with the prevention of igniting flammable gases and vapors in the vicinity significantly reduces the risk of explosion. Additionally, the National Electrical Code (NEC) published by the National Fire Protection Association (NFPA) requires that all lighting used in hazardous locations be explosion-proof.

Due to the specific design of explosion-proof lighting fixtures, the risk of explosion and fire is greatly reduced. Therefore, the safety of employees working in hazardous areas is significantly increased.

Let’s explore some benefits of LED explosion-proof lights that make them preferred choices:

Since explosion-proof lighting fixtures are typically made of stronger and heavier materials, they can withstand harsh working environments. Explosion-proof lights are more durable than standard lighting fixtures and are a better choice for illuminating certain workspaces.

LED explosion-proof lights have a longer lifespan compared to traditional explosion-proof lighting. These lights can work for approximately 50,000 hours in their initial brightness level. In some cases, even with continuous use, they can last up to 100,000 hours.

Thanks to their strong frame and thicker glass lenses, explosion-proof lamps are highly resistant to movement. Explosion-proof lights can be easily transported from one location to another using forklifts or other transport machinery without being easily damaged. Portable Advantages: Explosion-proof lighting fixtures are more portable compared to standard lights, making them ideal for professions that require mobile lighting solutions.

The main advantage of using LED explosion-proof lights over traditional lighting is energy efficiency, as they consume nearly 90% less energy than other lighting sources. Better durability and efficiency reduce maintenance and operational costs.

In addition to energy savings, LED explosion-proof lights do not contain toxic and hazardous substances harmful to the environment, such as mercury and lead. Therefore, using LED explosion-proof lights instead of traditional lighting options can make your business environmentally friendly.

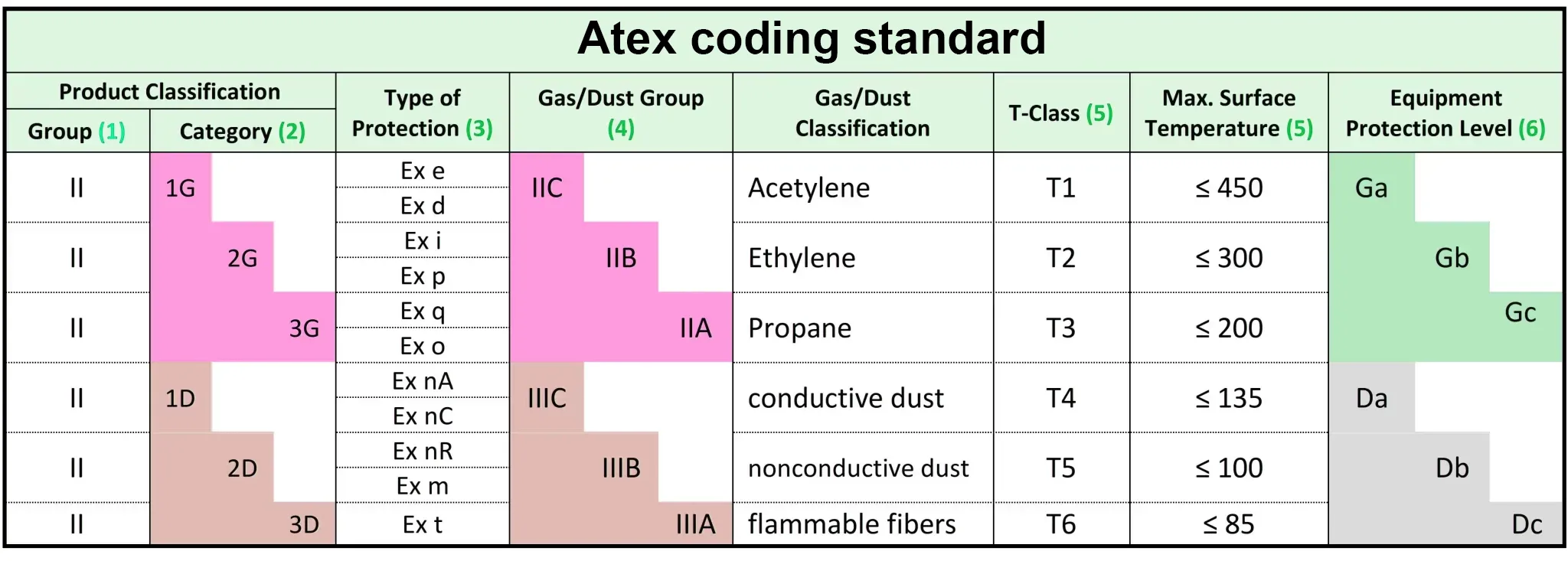

Typically, after the “EX” (explosive atmosphere) marking, a code consisting of numbers and letters is also indicated. This code represents the installation environment, type of protection, gas grouping, temperature class, and more, and it varies in different standards (CENELEC, ATEX, NEC 505, IEC). In this article, we will briefly explain the ATEX coding method. Shayan Barq’s industrial products are coded according to this standard.

The coding process of this method, prepared based on EU Directive 94/9/E and made mandatory for all European countries since July 2003, is as follows:

To +50°C Tamb= -30°C or Ta

| Zone Classification | Flammable atmosphere |

|---|---|

| Zone 0, Zone 1, Zone 2 | Gases |

| Zone 20, Zone 21, Zone 22 | Dust |

Selecting appropriate lighting equipment in environments susceptible to fire and combustion hazards can save human lives. Additionally, using LED explosion-proof lights can truly benefit your business.

For more information, please contact us, and to download the Shayan electric LED explosion-proof products catalog, you can proceed through the Downloads page